Ensuring quality in manufacturing often involves rigorous First Article Inspection (FAI) and Production Part Approval Process (PPAP) procedures.

However, these processes can be time-consuming and labour-intensive, especially for ballooning drawings and generating reports.

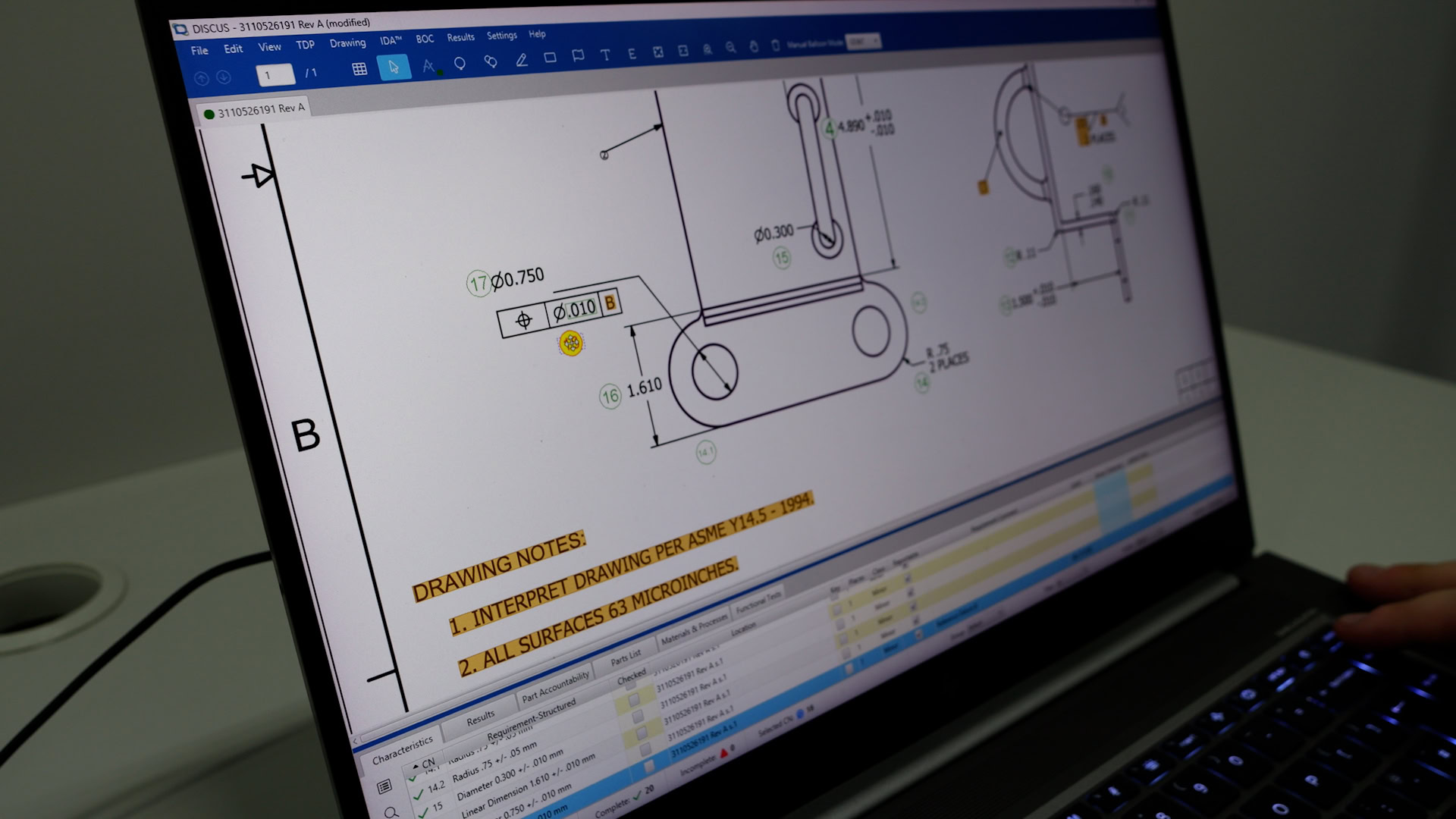

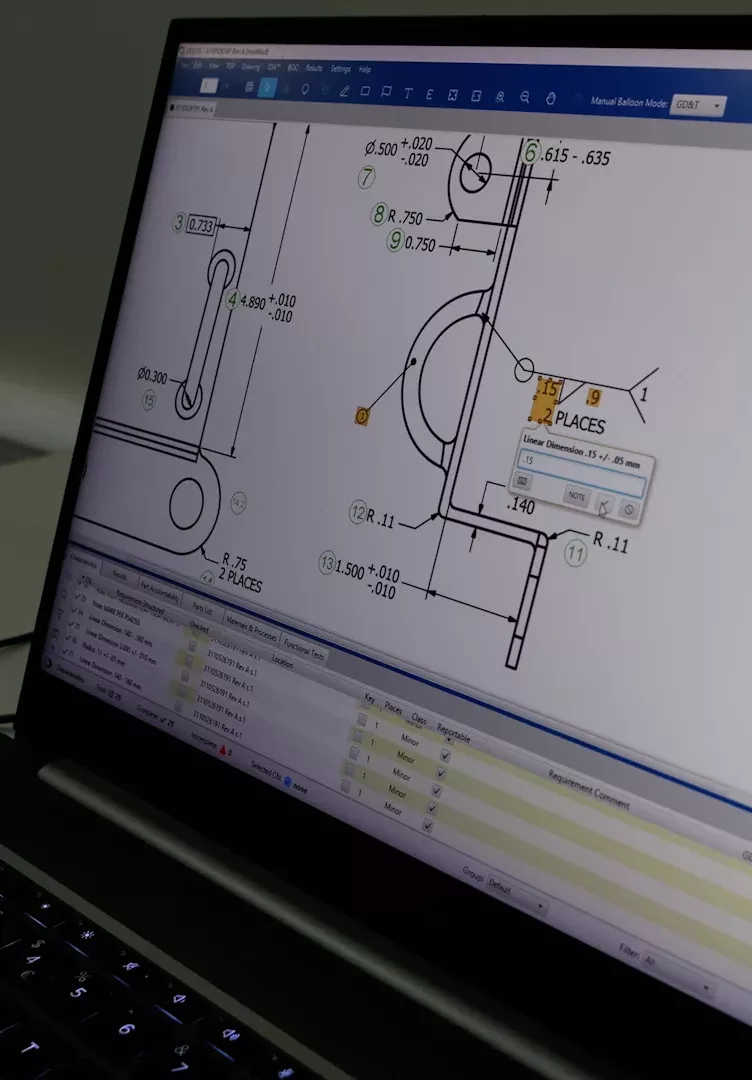

DISCUS software offers a comprehensive suite of software solutions to streamline FAI and PPAP for manufacturers. This powerful suite automates ballooning and reporting tasks, achieving significant time and cost savings.

Explore the key features of DISCUS and discover how it can transform your quality management processes below.

What is DISCUS software?

DISCUS offers a suite of software solutions to significantly reduce the labour efforts required for producing FAI and PPAP reports. DISCUS enables users to efficiently identify the detailed characteristics of a part model or drawing, derive the specific measurement requirements, and automate the generation of inspection plans by capturing images, drawings and specifications of the product.

As companies are complying with increasingly complex and diverse FAI expectations from their customers, DISCUS software offers world-leading ballooning and FAI reporting software that streamlines collaboration across supply chains, saving time, money whilst driving companies’ success.

Key features of DISCUS software

1. Reduce ballooning time by 90%

DISCUS software provides significant time savings, reducing average pdf drawings ballooning time from three days to twenty minutes, and allowing engineering teams to focus on more critical tasks.

2. Automate 80% of ballooning

DISCUS autoballooning software will automatically capture at least 80% of characteristics from engineering drawings, eliminating large amounts of manual work and ensuring consistency across production runs.

3. Export to any Excel templates

DISCUS software can export into any Excel template desired by the manufacturer, as well as FAI Reports, PPAP’s or AS1902RevC reports. This allows for effortless integration with existing workflows and reporting systems.

4. User-friendly interface

DISCUS utilises a user-friendly interface with clear, colour-coded tolerance indicators. This helps inspectors make faster, more accurate and informed decisions during quality checks.

5. Communicate with any CMM

DISCUS allows data to be transferred directly from any CMM or metrology device, automatically inputting inspection data from the machine into the software, saving valuable time and effort.