The DISCUS family of products is specifically designed to enable you to organise the technical data package or packages (TDP or TDPs) and capture the characteristic accountability of a part much more efficiently for the setup of the FAI process.

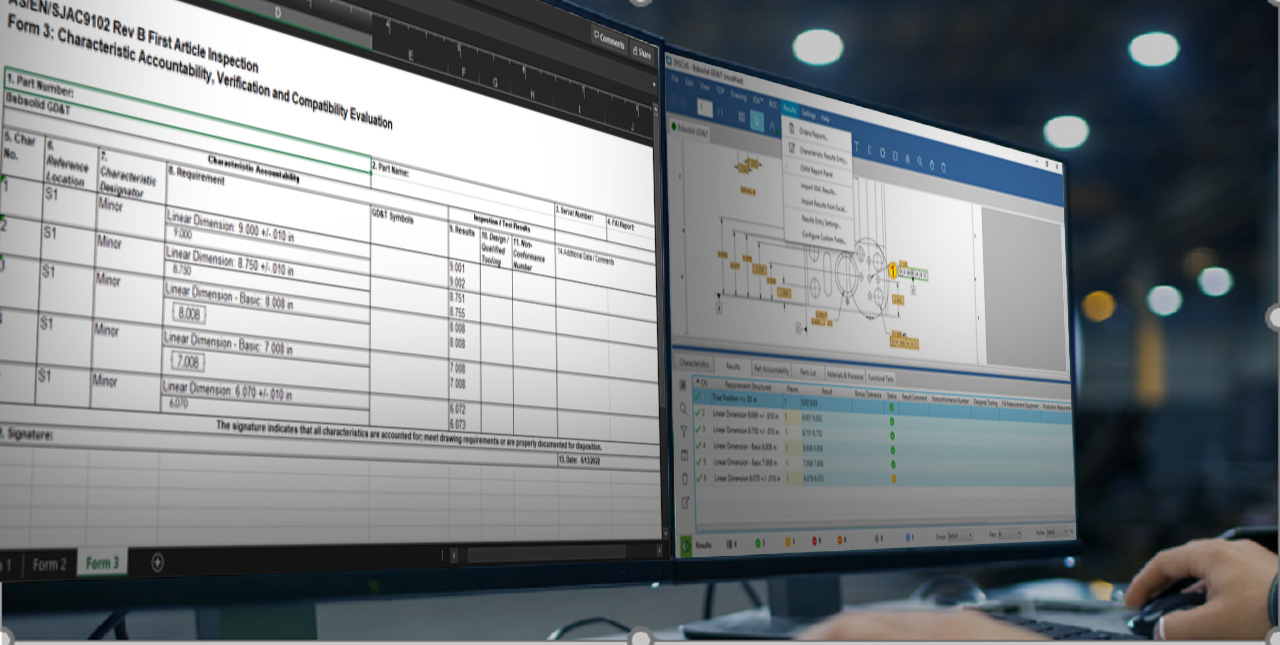

The DISCUS solution features a panel for analysing and extracting characteristics from the drawing or model, as well as from the specifications. DISCUS then generates the list of part-specific characteristics and creates associated ballooned drawings. Allowing you to consolidate and organise all your information, saving you time and money.

Reduces the time it takes to produce a First Article Inspection (AS9102, PPAP, Part 820) and ballooned drawing by up to 90% when compared to traditional, manual methods.

Reduces data entry labour and errors with automatic recognition of notes, dimensions and annotations from drawings, whilst consolidating all requirements into an accountability check list.

Import measurement information from any CMM or measurement device. Reducing manual data entry associated with reading CMM reports and entering onto a formal FAI report.

Print part drawing

Draw balloons on paper

Type data into Excel

Print Excel form

Write results on form

Enter results into Excel

Print completed FAI

1. Open drawing / Set up TDP

2. Establish

bill of characteristics

3. Enter inspection results

4. Export completed FAI

DISCUS has built-in Excel templates that are compliant with various inspection standards such as AS9102. However, it is also possible to create custom Excel templates to support formats for both internal and customer-required inspection forms.

Manage the Technical Data Package (TDP) and identify characteristics and requirements from 2D drawings and specification documents.

Allows users to automatically balloon an entire drawing page or specific areas in just a few clicks. This technology is groundbreaking in the world of 2D PDF and TIFF drawings.

Capture and verify actual inspection results without leaving the DISCUS tool. Enter the actual measurements and complete the entire inspection effort with the friendly and efficient user interface

Use the measurement values from the CMM report and incorporate them into the bill of characteristics, without requiring any special software on the CMM machine.

Book a free demo at our Advanced Innovation Centre and experience firsthand how DISCUS can revolutionise your ballooning process.

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU