Isolate data anomalies

GageStation is a full-featured data collection application that allows both manual and automatic data entry to identify and isolate out-of-conformance parts.

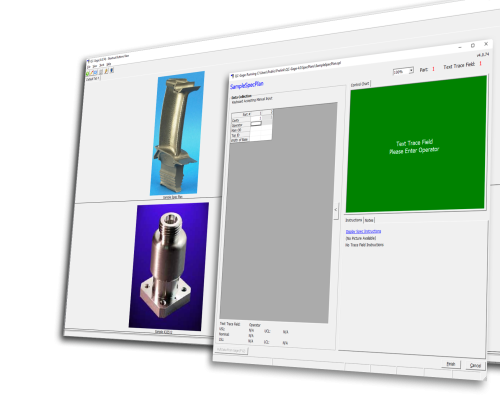

GageStation combines both QC-Gage and QC-CALC Real-Time in a full-featured data collection application for use with hand-held gauges. It allows both manual and automatic data entry to identify and isolate out-of-conformance parts to maintain complete control of the shopfloor.

QC-Gage is an inspection software that simulates the automated inspection technique of a CMM. It is programmed by simply answering questions that describe the sequence inspectors must follow. These ‘Spec Plans’ are saved and run by inspectors to create consistent inspection processes. After all the data is entered, it is then sent to QC-CALC Real-Time where it’s plotted to provide real time statistics and reporting.

GageStation combines data collection and inspection to create consistent processes, providing full understanding and traceability across the shop-floor.

Improved Process Control

Enhanced Decision Making

Regulatory Compliance

Detect and address process variations to improved quality, reduce defects and increase efficiency.

Identify trends, patterns and outliers to make data-driven decisions that optimise your processes.

Generate compliant reports, track audits and maintain documentation for regulatory purposes.