In the age of Industry 4.0, data is more vital than ever before.

Manufacturers who collect, report and analyse their data effectively possess a clear advantage in today’s competitive landscape.

Investing in data collection and analysis software embraces a data-driven approach, transforming manufacturing operations from reactive to proactive decision making, maximising productivity across the shopfloor.

Prolink UK offers a comprehensive range of data analytics solutions tailored to the specific needs of manufacturers. Whether it is a small workshop or a large-scale enterprise, Prolink UK has the expertise and technology to analyse all of the data from across the shopfloor.

How analysing all of your data with Prolink will lead to better manufacturing decisions

1. Gain full control & management of shopfloor data

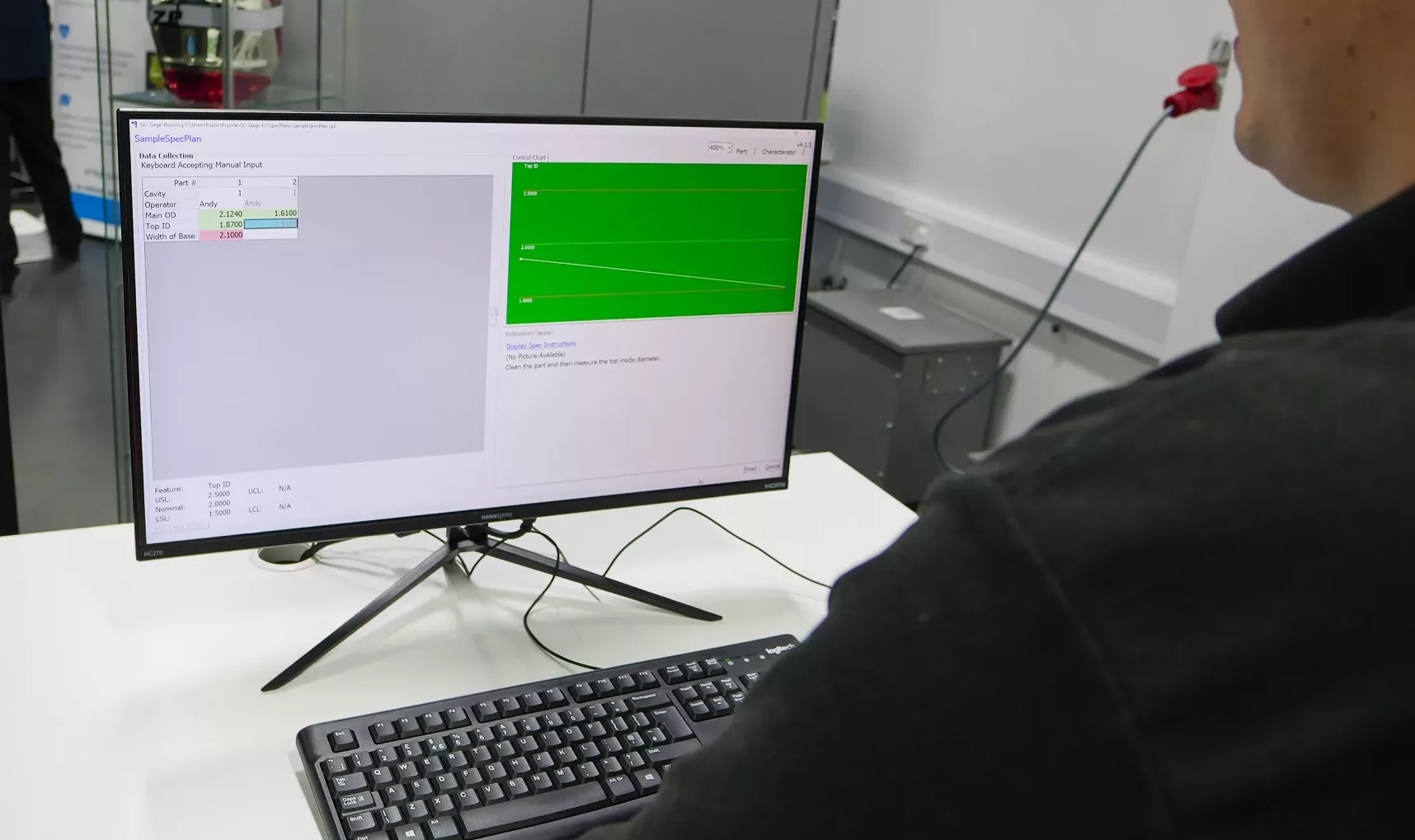

Prolink provides manufacturers with complete control of their shopfloor and production processes by uniting shopfloor data into a single, automated software solution. This comprehensive view allows manufacturers to make accurate, data-driven decisions for maximum efficiency.

2. Real-time feedback & response

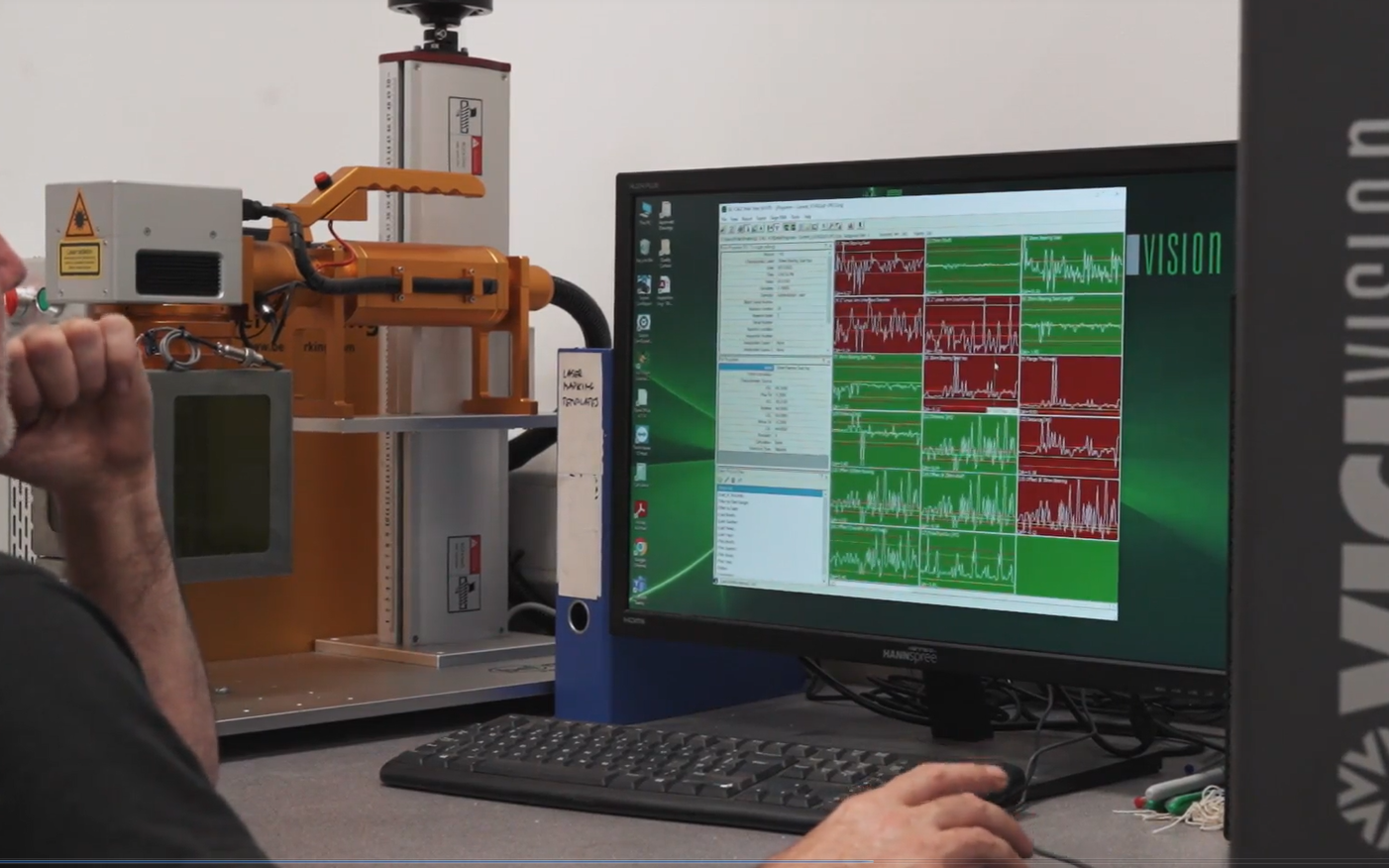

Prolink collects data from a variety of shopfloor technologies and analyses it in real-time, enabling continuous analysis and identification of any potential quality problems, trends or patterns, allowing manufacturers to proactively rectify any potential quality deviations that may have started to drift before they impact production.

3. Eliminate human error

Prolink’s automated data collection software solutions eliminates the risk of human error by seamlessly importing standardised, accurate shopfloor data, empowering proactive, data-driven decision making from reliable, real-time insights.

4. Management at every level

Organisations can customise data access and reports to specific sectors and roles to highlight particular product features, individual production runs, or machine performance. This targeted data access grants senior management a greater view of the entire shopfloor whilst providing machine operators with the specific data they need to perform their jobs effectively.

5. Fully adaptable to a range of manufacturers

Prolink’s variety of customisable reporting and dashboard capabilities provides a software solution that can be scaled to analyse the data of any manufacturing environment. This comprehensive data analysis informs accurate, educated and data-driven decision making at every level of the organisation.