Manufacturing execution system software (MES software) is a key part of Prolink UK’s suite of software solutions, monitoring the production process from raw materials to the finished product. MES software grants full transparency across the shopfloor, improving production and quality control processes.

Prolink offers intuitive, scalable and integrated software solutions that empower manufacturers with real-time data monitoring, automated reporting and unrivalled integration, elevating overall operational efficiency and product quality.

What is MES software?

Manufacturing Execution System (MES) software is a specialised software solution, primarily designed to support the manufacturing industry to monitor, manage, and control production processes on the shopfloor. MES software enables organisations to elevate their processes and remain competitive within their industry by streamlining operations, improving productivity, reducing costs, enhancing product quality and much more.

MES software connects multiple machines live production information across multiple sites, allowing data information to be accessed whilst on the go from wherever, whenever. This provides real-time production insights. MES software can integrate seamlessly with all shopfloor equipment and applications, resulting in complete visibility and control of production processes across any organisation.

Key features and benefits of MES software

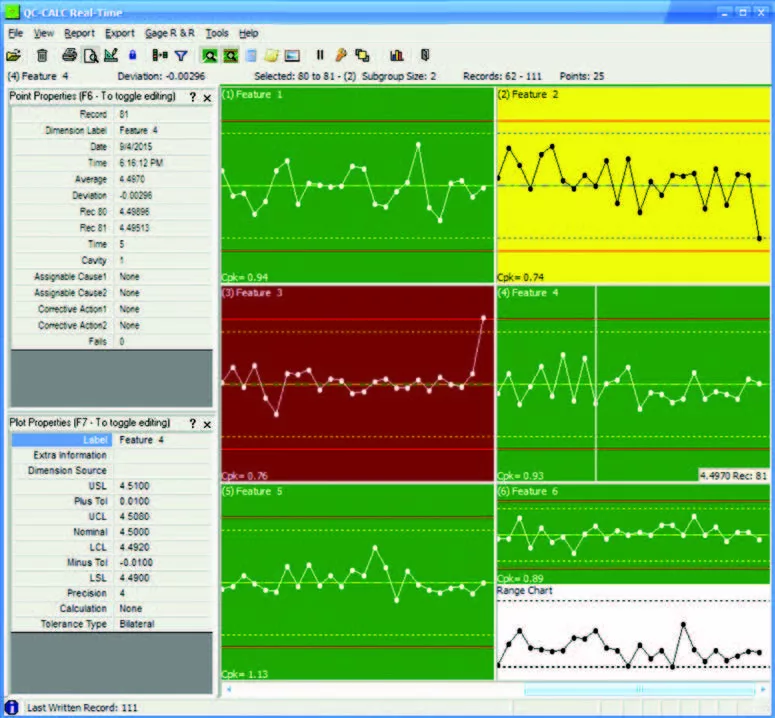

Real-Time Data Monitoring and Control:

Provides full visibility of machine status’, work orders, and production schedules. This allows for informed, data-driven, reactive and proactive decision-making.

Production Scheduling and Sequencing:

Aids in planning, scheduling, and sequencing production activities to meet customer demands and help optimise resources.

Quality Management:

Supports enhanced quality control by monitoring and managing product quality through various quality control processes. This ensures compliance with industry regulations and standards.

Inventory Management:

Enables the efficient management and tracking of inventory levels, from raw materials to finished goods, to reduce unnecessary costs.

Workflow Management:

Defines and manages workflows and processes involved in manufacturing, to ensure procedures are adhered to.

Data Collection and Analysis:

Automatically collects accurate data from a variety of sources and analyses the data to identify ways of improving efficiency, quality, and performance.

Traceability:

Offers full traceability of data to support reporting and manufacturing analytics.

Performance Monitoring and KPI Reporting:

Provides Key Performance Indicators (KPIs) and performance metrics. This allows senior management to identify ways to maximise productivity, measuring the effectiveness and efficiency of the manufacturing process.

Integration:

The flexibility of MES software seamlessly integrates with a variety of enterprise-level software to ensure strong communication and coordination across any organisation.