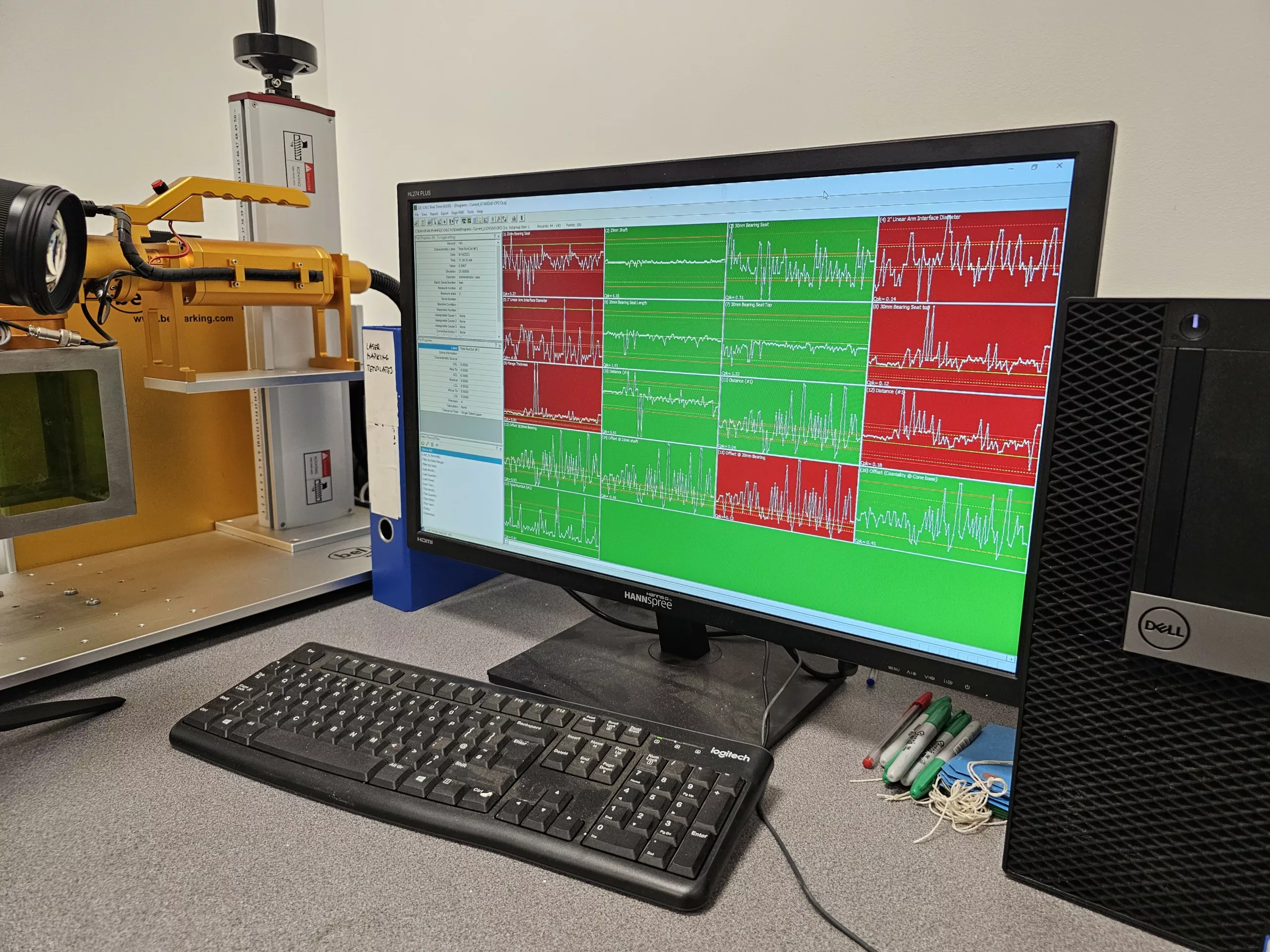

Statistical Process Control software (SPC software) is a key part of Prolink UK’s suite of software solutions, automating data collection and quality analysis across any organisation. SPC software elevates shopfloor efficiency and productivity by granting greater visibility and control over real-time production processes.

Prolink UK offers intuitive, scalable and integrated software solutions that empower manufacturers with real-time data monitoring, automated reporting and unrivalled integration, elevating overall operational efficiency and product quality.

What is SPC software?

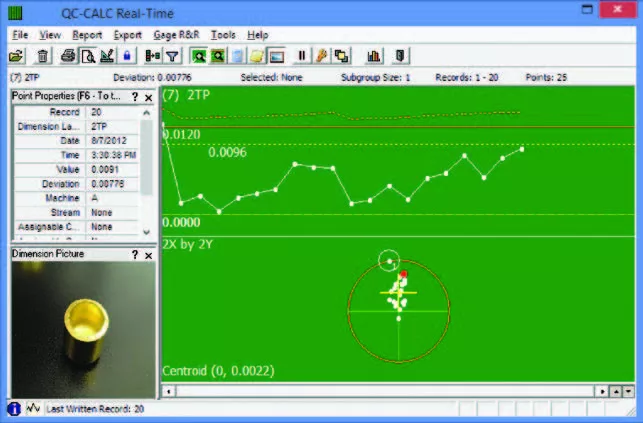

Statistical Process Control software (SPC software), is a quality control and inspection software that measures the consistency of a products performance according to its original design specifications. SPC software monitors process behaviour, identifies internal system issues and offers real-time solutions within production.

SPC software is primarily designed for the manufacturing and production sectors, ensuring continuous statistical surveyance, analysis of measurements, and verification of product performance within specific distributions. Implementing real-time quality SPC inspection software allows for shopfloor problems to be caught at a much earlier stage, identifying the root cause and immediately responding to rectify the issue. SPC software provides the collection, visualisation, and analysis of data to help minimise variability during production processes, improving the quality of service and of the end product.

Key features of SPC software

Key benefits of SPC software

- Automatic data collection and analysis.

- Collects data from a variety of sources such as sensors, measurement devices, or manual entry.

- Monitors production processes in real-time.

- Identifies and analyses patterns and anomalies.

- Produces bespoke graphs to analyse data.

- Conducts comparative and analytical reviews of components against original design specifications.

- Identifies the root cause of any variations or defects within the production process.

- Reduces scrap and reworks.

- Guarantees quality and consistency in end-products.

- Maximises productivity.

- Identifies and rectifies issues during the production process.

- Extensive and bespoke analytics and reporting.

- Instant and scalable PDF reports.

- Full transparency of data and trends.

- Greater synergy across the shopfloor.

- Improved resource utilisation and operational efficiency.

- Reduced costs.

WANT TO FIND OUT MORE?