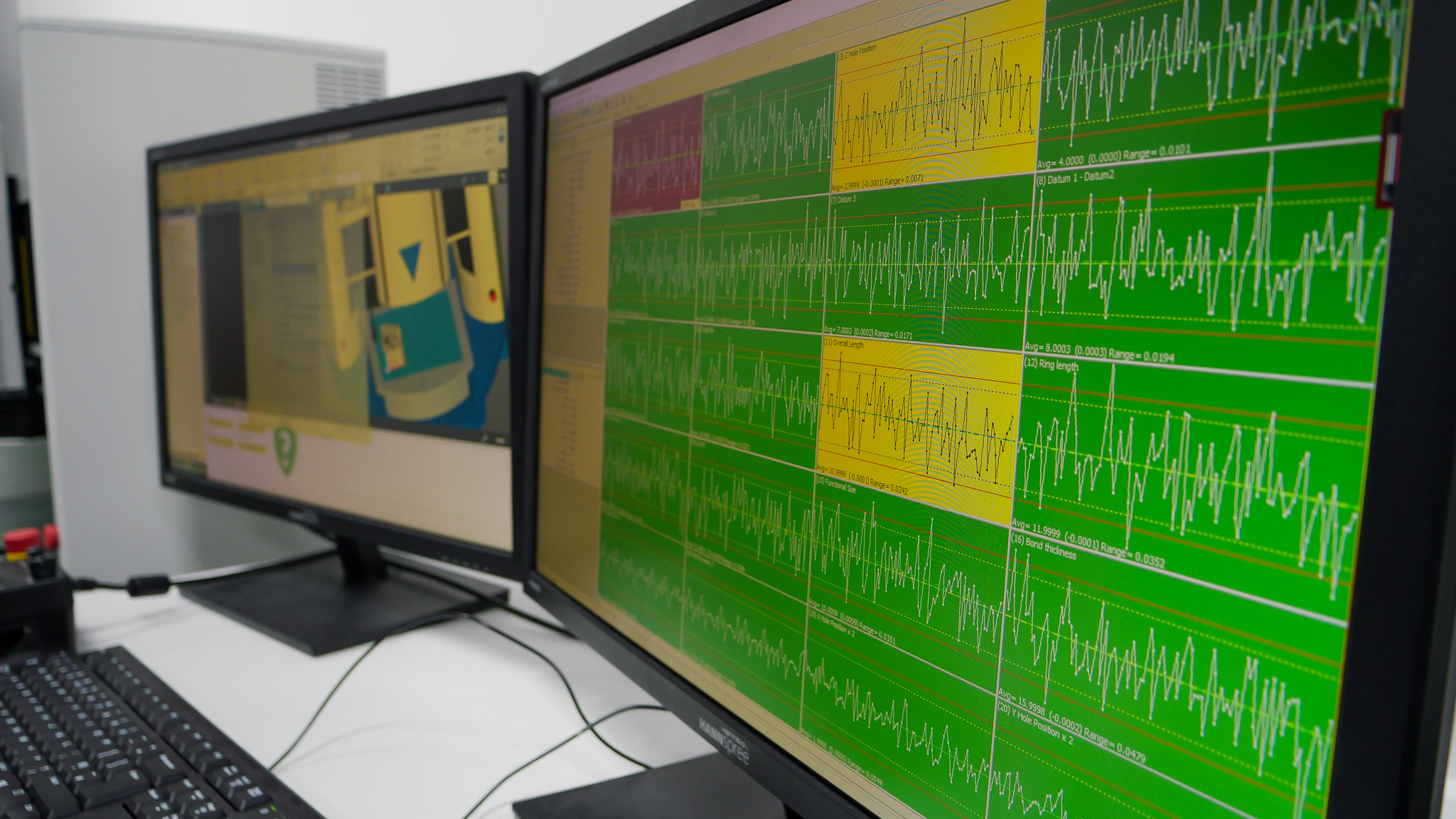

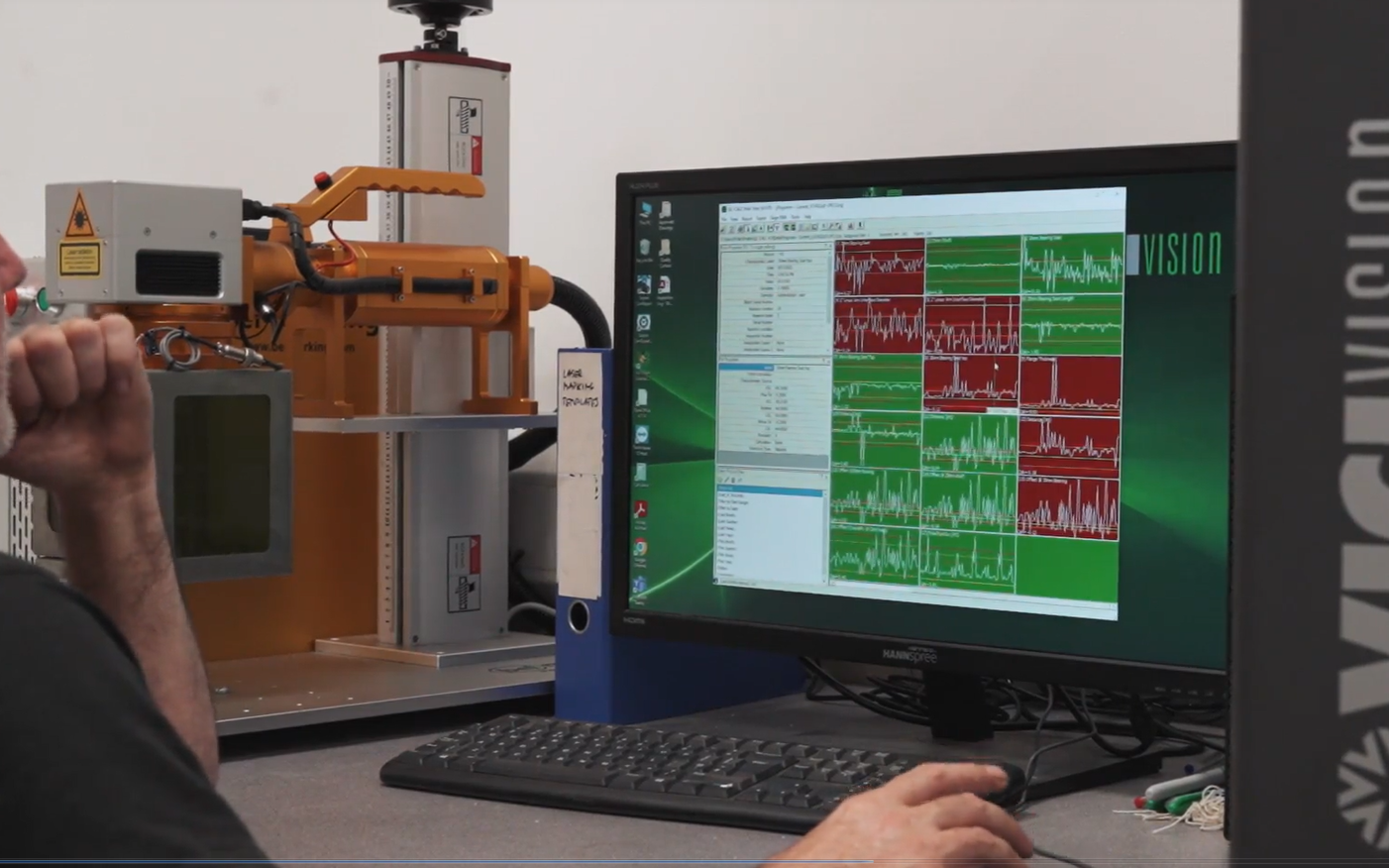

In the modern manufacturing world, Statistical Process Control (SPC) is no longer a formality but essential for achieving operational excellence, demanding robust solutions that seamlessly integrate with existing infrastructure and empower informed decision making.

Prolink offers an intuitive, scalable and integrated software solution that empowers manufacturers with real-time data monitoring, automated reporting and unrivalled integration, elevating shopfloors to unparalleled operational efficiency and product quality.

What sets Prolink apart from other real time data collection & SPC packages?

Seamless integration

Prolink seamlessly integrates with any shopfloor setup and can collect data from the largest number of CMM and gauges in the world. This compatibility allows users to harness existing data for instant shopfloor data insights.

Expert service & support

Supported by a dedicated UK team, Prolink offers expert SPC guidance through training, on-call support, and remote/in-person assistance, ensuring users get the most out of Prolink’s data collection, analysis and quality control software.

Global access to data

Prolink’s cloud-based data collection and analysis software access allows senior management to remotely monitor shopfloor data anytime, anywhere and from any device informing reliable, data-driven decisions.

Historical data on demand

Prolink empowers proactive problem solving with instant access to historical data, revealing patterns, trends and identifying the root causes of issues for shopfloor-wide quality improvement.

User friendly software

Prolink empowers users of all abilities to optimise the shopfloor with its intuitive interface, automating data collection and analysis to make quality insights effortlessly accessible and actionable.

Scalable software solutions

Prolink’s flexible, customisable software solutions scale from a single shopfloor to global organisations with multiple sites, tailoring quality control to every shopfloor’s needs, from basic statistics to enterprise-wide insights.