Act quickly on problem parts

Remove problem parts easily with colour-coded squares to identify dimensional and tolerancing issues. QC-Sort is adjustable and easily configured to display the physical layout of your parts as they are fixtured.

Fast part analysis

QC-Sort is a non-statistical application used in conjunction with QC-CALC Real-Time to quickly identify bad parts on a multiple-part inspection fixture.

Live displays

QC-Sort is adjustable and easily configured to display the physical layout of your parts as they are fixtured.

Sort your way

Create a sort plan to determine acceptable dimensions and tolerancing. Once established, the closed-loop system will help operators to identify bad parts.

Benefits of QC-Sort

Automatic monitoring

Automatic monitoring of QC-CALC Real-Time data allows seamless integration and users to be hands off with the sort plans during inspection.

If any characteristic on a part is out of specification, that part is considered a bad part and is displayed in red. All good parts are displayed in green.

Partial batches can be handled with a quick adjustment, automatically displaying the partial batch and returning to normal for the next batch.

The history panel displays up to five past batches on the right side of the screen. Click on the past batch of interest to see it as the main display.

Pictures can be used in place of coloured rectangles to help operators remove the correct parts from the fixture.

Fast.

Accurate.

Powerful.

Precision.

Automated.

Reliable.

Repeatable.

Unbeatable quality.

Improved process control

Detect and address process variations promptly, leading to improved quality, reduced defects and increased efficiency.

Enhanced decision making

Identify trends, patterns and outliers to make data-driven decisions that optimise processes, minimise risks and improve overall product quality.

Regulatory compliance

Easily generate compliant reports, track audits and maintain documentation for regulatory purposes.

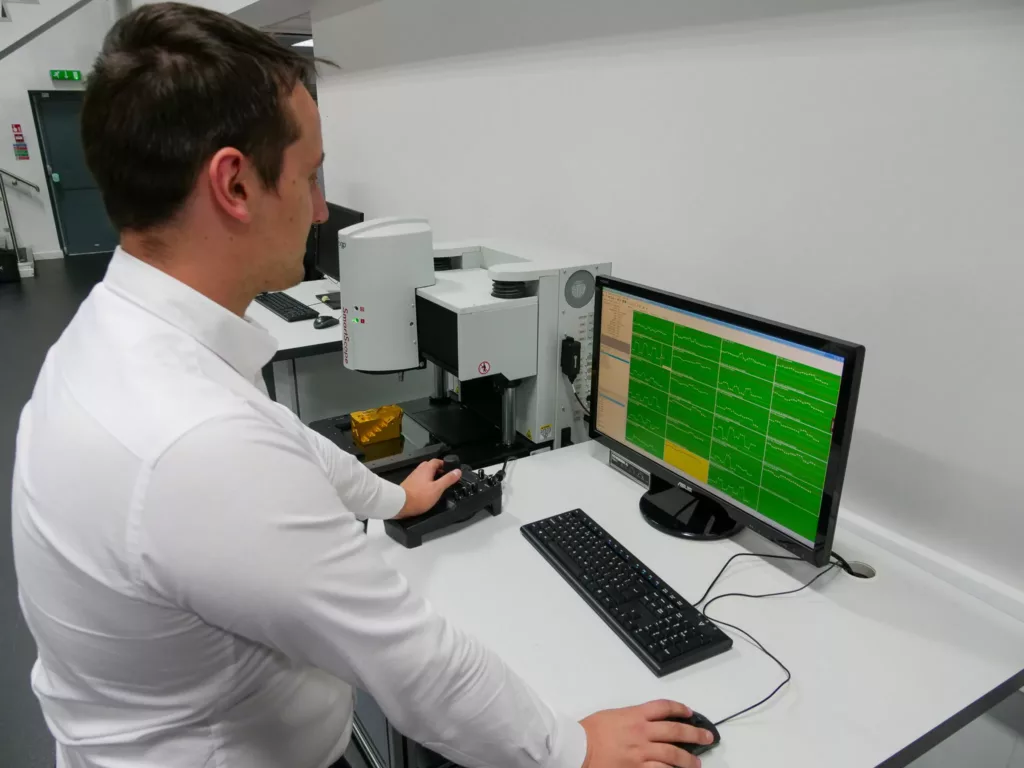

Book your

in-person demo

Book a free demo at our Advanced Innovation Centre where you can get hands on with QC-Sort software to discover the benefits to your measurement routines.

Download the full specifications

Get the full technical data on QC-Sort today. Discover the full capabilities of QC-Sort, including set up and how it can transform your inspection.